A. Background:

Lead (Pb) containing solders are being replaced by lead-free

solders because of environmental concerns. In addition to

environmental problems, the technical limits of tin-lead solders,

in particular its

relatively low-strength, are

currently being reached as component operating temperatures are

increasing and finer pitch components with smaller solder joints

are becoming the industry standard. The manufacturers

have to change fast over to

the lead-free alternatives because of legislation and laws being

introduced to check the use of lead based materials in

electronics industry. But, there is not much detail available on

the

thermo-mechanical behaviour

of various lead-free solder alloys with respect to different

components and finishes on PCB. The manufacturers also want to

have a rapid test method to compare the joint reliability.

This project proposes to

develop a rapid reliability test method for comparing solder

joints with different alloys and components.

B. Proposed

Research: To date, a large proportion of the work

undertaken on lead free solders has concentrated on chemical

composition of alternative solder alloys and their compatibility

with different sets of PCB

finishes. Manufacturing

related issues are also being reported. But there is little, if

any, work reported on the mechanical reliability and strength of

lead free joints. Currently in NMRC work has been going on to

develop a means of measuring

the mechanical behaviour of a range of lead-free solder materials

through the design and test of specimens, which reflect real

joint behaviour. Usually the reliability tests take too long

and sometimes can go as long

as six months. Some rapid testing has been reported for

lead-based solder joints but currently there is no available

rapid test method that allows judging the reliability of solder

joints.

Therefore the objectives of this project are:

The novel aspects of this project will be:

The work plan for this project is to start with the review of

literature of lead-free solder development and new rapid testing

methods. This will go alongside in getting acquaintance and

experience with

various processes and equipments to be used for this project.

This include the assembly process of the PCB, using mechanical

testers (INSTRON and DAGE) and various reliability test processes

like

thermal vibration, thermal cycling tests, etc. After this stage,

the reliability testing of conventional lead-based solder joints

will start. This will go alongside with finding new techniques

for rapid testing of

these joints. This includes the combined heat and vibration

testing and the behaviour of yield strength of solder joints with

respect to temperature. Next, the numerical modelling will

commence as well as the

systematic study and comparison of various lead-free alloys and

components. The above description is presented in the form of bar

chart in the page attached.

The end result of this project will be to develop a rapid

reliability test method for the solder joints. It will also

provide a database of results on the reliability of lead-free

solders. The numerical model

developed in this project will also provide a reliability

prediction methodology strongly based on measured data.

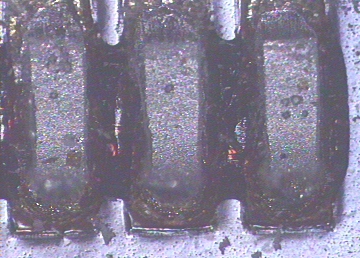

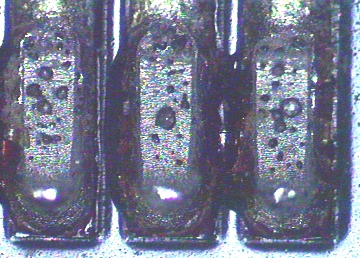

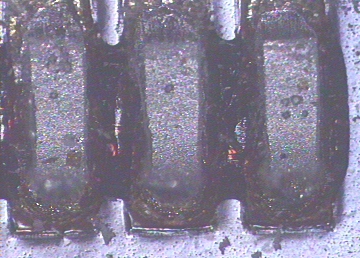

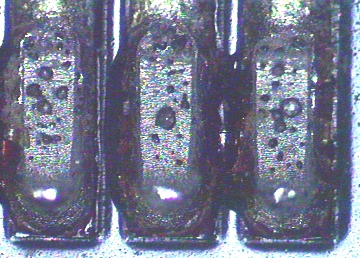

The above images show the solder pads after the leads have been

pulled of. Voids on the pads can be seen very clearly.

Developments

The project has changed a lot since its inception. The pull test and shear tests are no longer a part of the project as they are unable to replicate the same failure mode and mechanisms in thermal cycling test, which is the most common reliability test for solder joint.

The three tests that have been selected are :

Animations showin cyclic displacement, bending and twisting test respectively.

These tests are able to induce plastic strains in the joints in the same way as thermal cycling. However, since the effect of CTE mismatch is not included in mechanical cycling, the failure mechanisms are not same. In thermal cycling failure the most common failure mechanism is inter-granular in nature, associated with low cyclic strains and accompanied with grain boundary sliding. In mechanical cycling, due to higher stresses, the failure mechanism in trans-granular in nature. Efforts are curently underway to combine thermal and mechanical cycling, in order to get the required failure mechanism. Initial results, both on QFP and BGA, are promising.

FEA/FEM simulation

This project involves lot of simulation work as well. Simulation of thermal cyclingon QFP and BGA has been caried out in order to save time taken in experimentation. The simulation includes transient and non-linear behaviour of solder joints (In ANSYS Anand's model has been used). By calculating Plastic work energy, number of cycles to crack initiation and crack propagation rate during thermal cycling has been calculated. Fig. 6 shows the plastic work energy in Gull-wing lead during one cycle of thermal cycling. The figure clearly shows the crack growth path in the joint.

Fig. 6 Plastic Work energy in QFP solder Joint

This page was last updated on 8th Feb. 2001.

Copyright: Yasir A. Quadir, UCC, NMRC